What is Takt time?

Are you interested in reducing waste as a result of better planning? How about creating a continuous work flow which helps you meet your project’s deadline and reduces your waste? Former colleague Abdallah Baydoun explains the basics of Takt time planning in the post below.

It is neither rocket science nor magic, achieving these goals is simpler than you think. In fact, whenever I explain to managers about takt time planning, I always feel their confusion, as if they are still waiting to hear something new that ‘’they do not know’’. Hence, the concept is really familiar to us, however many lack a systematic approach to implement it.

In this post, I will first uncover the basics of takt time planning by shedding the light on its definition. Then, I will state the systematic steps based on best practices that you can follow which will help you make your project leaner.

What is Takt time?

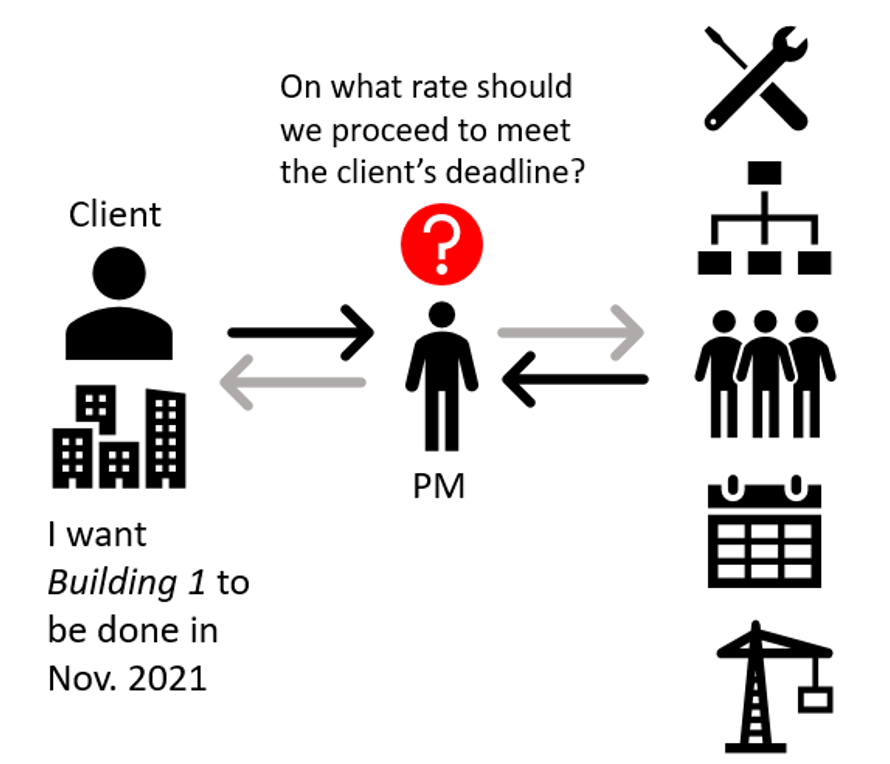

Takt is a German word for rhythm, or pace and it represents the unit of time within which an item should be produced to meet the client’s expectations. In other words, it is matching the production supply rate with the client’s demand rate. But this sounds very specific to production, what about construction or projects in general? Hence, I personally would like to define takt as the ideal pace within which a work package is handed over by one trade to the other, allowing a uniform workflow that is designed to meet the client’s demand. Note that I stated the words ‘’Ideal and uniform’’, this is because in reality not all trades produce at equal rates. However, if we would accept waste in our project, then takt can be redefined as the maximum allowed time per unit for all trades to meet the client’s demand.

Ok, now what?

Since defining our takt is demand based, we need to know how fast our work should flow to meet our deadlines. This imposes the biggest challenge for project managers and planning engineers especially if they are aiming to create an ‘’ideal’’ workflow pace for every trade in the project that is waste-free.

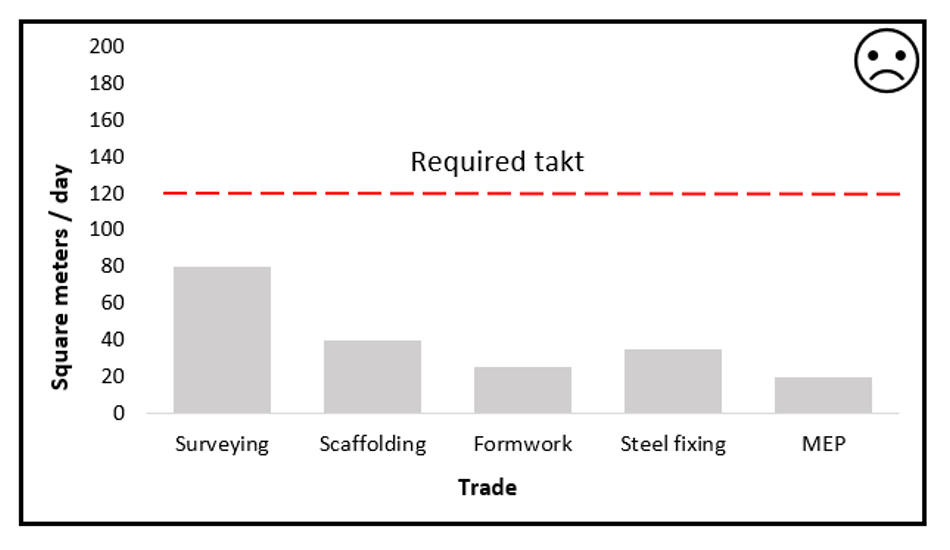

Since, if some trades are progressing faster than takt, this would lead to excess buffers or unnecessary inventories and thus, waste. Nevertheless, if some trade’s workflow moves slower than takt, those trades will take longer time to finish which will consequently delay their successor activities. Hence, it is essential to use a systematic approach that will help us develop our takt and avoid those situations as much as possible.

The 5-step approach

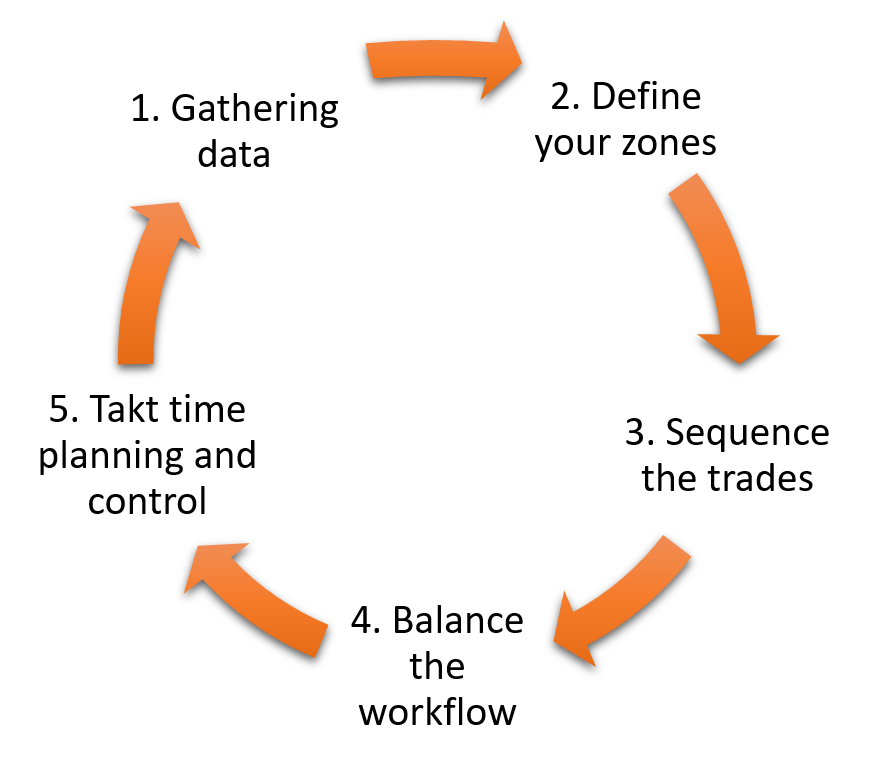

Step 1: Gathering data

Prior to execution you need to know what and where exactly the work is to be done, how many trades are involved, and in what sequence these trades can proceed. This is a vital exercise since you will need the input of the people on the job (the last planners). The goal is to avoid pushing a schedule that trades should fulfil and rather to pull a preferred plan from those trades. A good start can be asking each trade what they need to finish their task, and you should encourage any comment or suggestion. Note that there is a great opportunity of integrating both the Last Planner System® and takt time planning to achieve even better results. At the end, you need to develop a workable flow that fits every trade’s expectations, leading to reduced task variability and ultimately a continuous workflow.

Step 2: Define your zones

Information from step one can be used to divide your project into zones. Zones are the physical areas where trades operate, and ideally the zones should be defined in such a way that all trades working in a specific zone take the same amount of time to complete their tasks in that zone.

Step 3: Sequence the trades

Now that you defined your zones, you are better able to pull the sequence of trades by arranging coordination meetings. You need the collective input of those trades to collaboratively plan which trade goes first due to necessity or optimality. At that stage, you can establish an agreed methodology of how work can flow between the various trades.

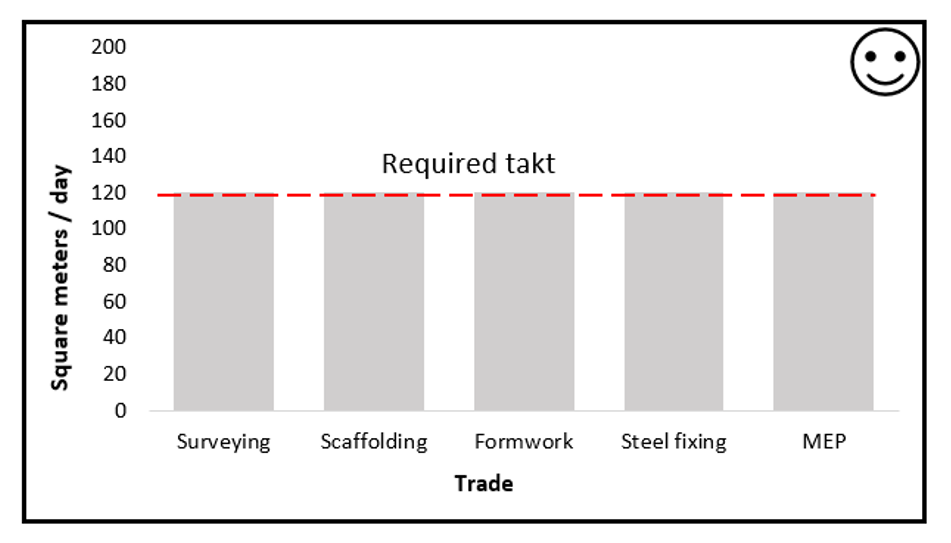

Step 4: Balance the workflow

You established your zones, and sequenced the trades, however it is never the case that you have a balanced workflow without some iteration. You should be on the lookout for bottleneck trade activities that need to go faster or slower to match your required takt or even you might want to readjust your zones. Prefabrication? Adding resources? More equipment? It is time to be creative!

Step 5: Takt time planning and control

The balanced workflow rate at which activities progress in your defined zones is your defined takt time. Nonetheless, activity first trails are essential to determine the soundness of your planned takt time. Hence, you should continuously track progress to proactively note deviations from the desired takt time and take proper control actions.

Example

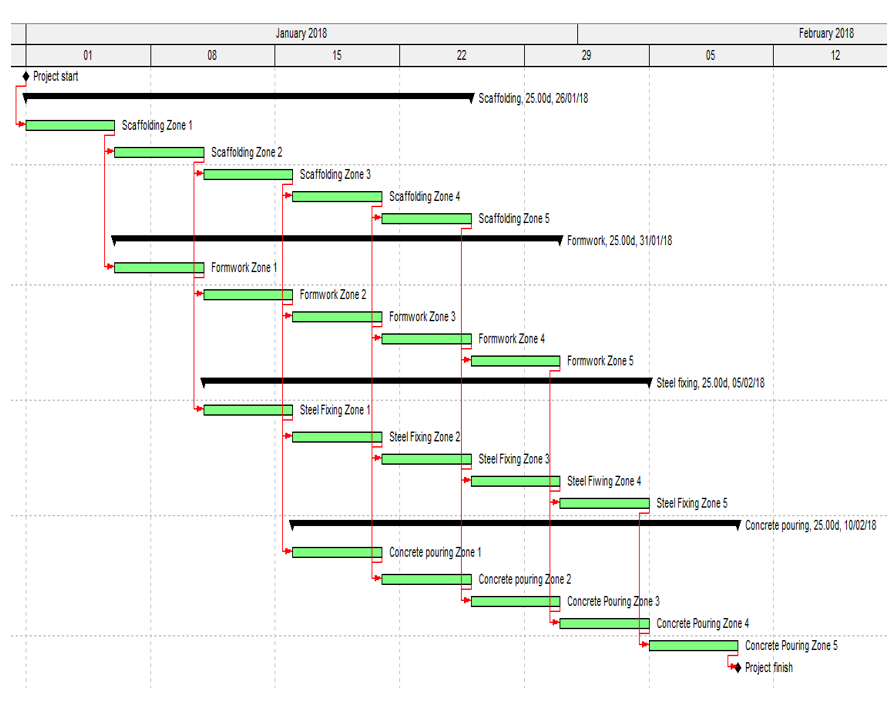

Although very simplistic, the following picture demonstrates a project that is ideally planned according to takt time. Even better visualizations can be done using linear scheduling using time-location planning software.

Conclusion

Given the available literature and the absence of fixed definitions, takt time planning remains a hot topic that is open to improvement, however the results from implementing takt time planning are game changing. So, if takt time planning sounded like something you are interested in, search no more, Proove is your go-to trusted partner for advice and implementation.

Ed. This article was written by former colleague Abdallah Baydoun.